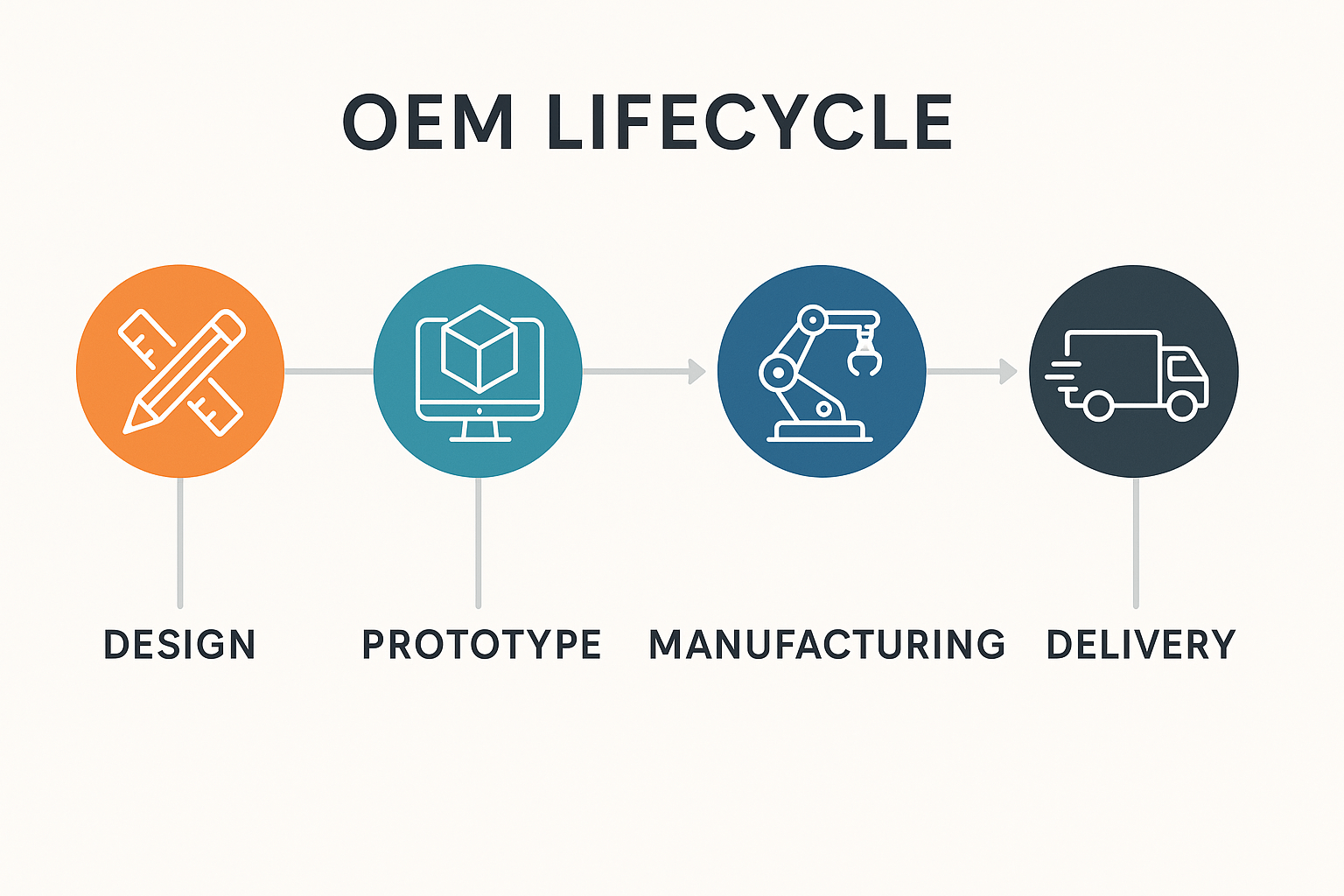

The journey of an electronic device — whether it’s a feature phone, charger, power bank, or TWS — doesn’t begin at a retail store or online listing. It begins long before that, inside an OEM (Original Equipment Manufacturer) facility, where ideas are turned into reality through a strategic and highly coordinated process.

In this blog, we will take you through a step-by-step breakdown of the OEM manufacturing lifecycle, offering insight into how OEMs — like Tryto Mobitech — conceptualize, build, test, and deliver finished products for brands and consumers alike.

🧠 1. Ideation & Product Conceptualization

Everything starts with an idea — whether it’s a market demand, a technological innovation, or a custom request from a brand partner.

During this stage, OEMs:

- Conduct market research

- Study competitors and trends

- Define product functionality and target audience

- Create a product requirement document (PRD)

💡 Example: A brand wants a feature phone with an emergency SOS button for senior citizens. The OEM team works with them to map out the design, specifications, and functionality.

🖊️ 2. Design & Engineering

Once the concept is finalized, the design phase begins. This involves both industrial design (how it looks) and hardware engineering (how it works).

Key activities include:

- 2D/3D CAD renderings

- Component layout and internal schematics

- User interface and control design (if any)

- Material selection and feasibility analysis

Designs must be aesthetic, functional, and production-friendly.

🛠️ OEM Tip: Good design balances innovation with manufacturability — overly complex designs can drive up cost and delay timelines.

🔬 3. Prototyping & Validation

This is where the first physical sample of the product comes to life.

OEMs typically create:

- 3D-printed casing prototypes

- Working electronic circuit boards

- Mockups to test ergonomics and usability

Testing includes:

- Drop tests

- Button responsiveness

- Port placement accuracy

- PCB functioning

Multiple iterations may be required to reach a validated prototype ready for mass production.

🧪 4. Testing & Quality Assurance

Before a product enters mass production, it must pass stringent quality and safety standards.

This includes:

- EMI/EMC testing

- Battery safety checks

- Electrical safety

- Compatibility with chargers, accessories, and networks (for phones)

The QA department also runs:

- Functional tests

- Stress tests

- Aging tests (e.g., continuous operation for 72+ hours)

- Environmental tests (heat, cold, humidity)

✅ OEM Insight: Early testing helps catch costly flaws before mass production begins.

🛠️ 5. Tooling & Molding

Once the product is approved, tooling begins — a critical investment-heavy phase.

It includes:

- Creating molds for plastic injection

- Setting up SMT (Surface Mount Technology) machines

- Preparing jigs and fixtures for assembly lines

Tooling can take 2–6 weeks depending on complexity.

🧰 OEM Note: Molds need to be precise — even a 0.1 mm defect can cause issues in final assembly.

🏭 6. Mass Production & Assembly

This is where the magic happens — the factory floor comes alive with synchronized assembly lines producing hundreds or thousands of units per day.

Steps include:

- PCB assembly (SMT or manual)

- Component soldering

- Casing attachment

- Display and battery integration

- Final product sealing and labeling

Robotics, automation, and human assembly lines all play a role in making the process efficient and error-free.

🧪 7. Final Testing & Inspection

After assembly, each unit undergoes final QC checks to ensure consistent quality.

Tests include:

- Functional button testing

- Display and speaker checks

- Charging and battery verification

- Camera or microphone checks (if applicable)

Any faulty units are reworked or scrapped. OEMs usually operate with <1% defect tolerance.

🔍 OEM Assurance: Every batch is accompanied by QA reports and compliance certificates (e.g., BIS, RoHS, CE).

📦 8. Packaging & Branding

Once cleared for delivery, the product goes through:

- Custom packaging based on client’s brand guidelines

- Accessory inclusion (charger, cables, warranty card)

- Barcode tagging and inventory management

- Brand/logo printing (often via heat press or UV printing)

OEMs often maintain packaging SOPs for different clients and ensure damage-proof packaging during transit.

🚚 9. Logistics & Supply Chain Coordination

Finished goods are now handed over to logistics — a vital phase where timeliness, tracking, and cost efficiency matter most.

OEMs manage:

- Warehousing

- Domestic or international shipping

- Order tracking and batch numbering

- Coordination with freight carriers

📦 Pro Tip: Smart OEMs integrate ERP systems for inventory visibility and just-in-time delivery.

📊 10. After-Sales Support & Feedback Loop

Top-tier OEMs don’t stop at delivery — they offer after-sales support, warranty tracking, and even product performance insights.

This includes:

- Handling replacements or DOAs (dead on arrival units)

- Sharing performance reports

- Logging customer complaints

- Improving future iterations based on feedback

This closes the loop, helping brands deliver better user experiences and OEMs improve product offerings.

🔁 The Lifecycle Is Continuous

Every new product feeds into the next — better learnings, enhanced tooling, new features, faster turnarounds. OEMs constantly refine:

- Design practices

- Supplier quality

- Compliance procedures

- Assembly line workflows

OEMs that own their full lifecycle — from design to delivery — are more agile, consistent, and trusted by their partners.

🧭 Conclusion: Why OEM Lifecycle Mastery Matters

Understanding the OEM manufacturing lifecycle isn’t just about processes — it’s about unlocking efficiency, quality, and innovation.

Whether you’re a startup looking to build your first device or a major brand outsourcing large volumes, working with an OEM that masters every stage of the lifecycle gives you a competitive edge.

From the initial sketch on paper to the final product in a consumer’s hand — OEMs make it happen. Efficiently. Reliably. Repeatedly.

Add a Comment